grumpy

Well-known member

Never done it, cause...........I never had to. LOL.

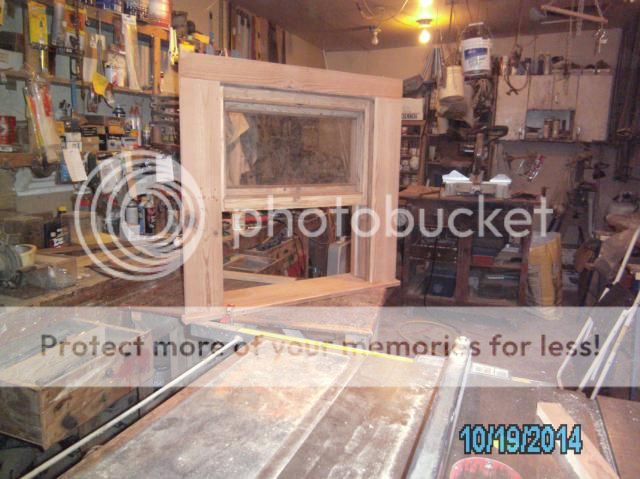

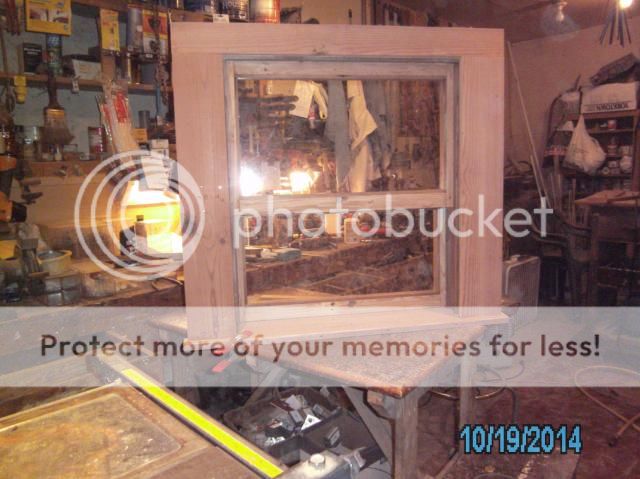

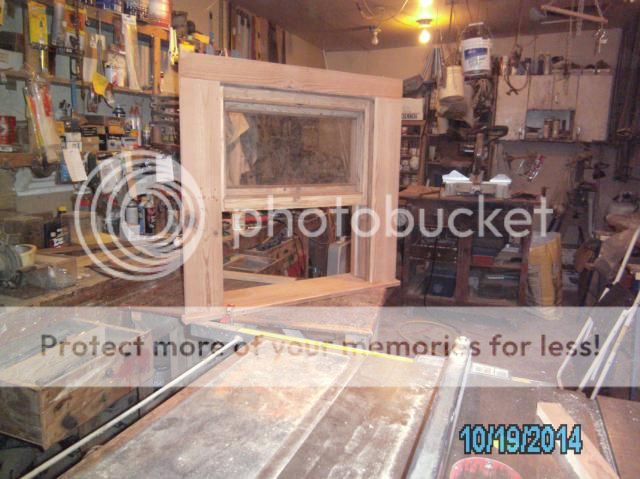

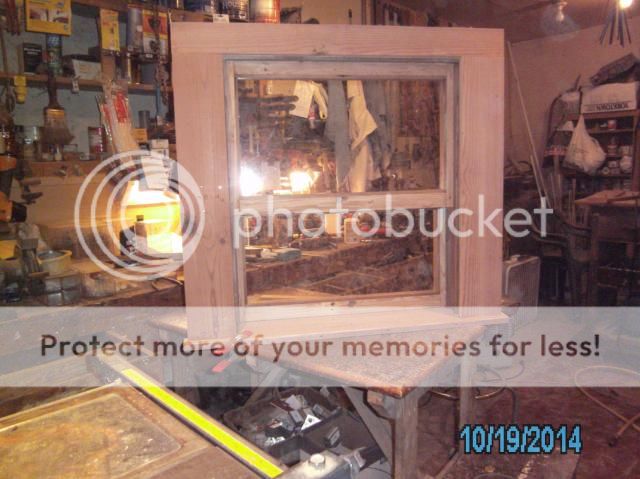

Being a tight-###, I nearly stroked when I learned the cost of a

double-hung, wooden window that had to be custom ordered because

the size is no longer manufactured.

A former tenant "decided" to demolish an existing window and replace

it with a solid, single pane, plastic, who-knows-what.... :evil: :twisted: :evil: :twisted:

I've been blessed with the appearance of an enthusiastic, young man who's

pretty handy and doesn't mind working as a new tenant. Only, he "Ain't

"real-good" with cabinet making." (his words...not mine.)

"We gotta do something with that window, Sir. That's what's causing all the

water damage."

I had to agree.....but $200.00 for a replacement window on a custom size

was a little too steep for my blood.....or a rental house for that matter.

I thought..........well *^&%$*&..maybe I can do it....

Wasn't real sure..but what the heck. I went scrounging around the barn

and came up with some RE-PURPOSEFUL lumber.

1) Some 3/4" pine 1X12's I pulled out of a dumpster.

2) 1- 8 foot cedar 1X6 that came off of an old hot-frame in my greenhouse.

3) 1- 12 foot 2X4 taken from a horse stall I'm taking apart anyways.

4) For the glass, I used one-eighth inch Lexan plastic. Unbreakable.

Note: All of the above was "free"...I like that price.

Yes.........the trim is OVERSIZED by quite a bit. But, unless I was the one

that took the measurements, I couldn't be exact enough for the new trim

to butt up against the existing lap siding.

I located the center of the window for the young man and told him to do

the same thing with the rough opening. Then measure each side from the

center to the edge of the siding and mark the trim accordingly.

Then.....very carefully use a skill-saw and cut to the ""inside"" of the mark.

He had a funny look on his face as if I was mistaken.

I grinned, "No, trust me, that extra eighth inch will be easily caulked in and

you won't have to make the cut but one time."

He understood my meaning.

Overall, it didn't turn out too bad. I boo-boo'd on the sash-frames by 3/4"

on the top one. That made it "larger/taller" than the lower.

I made the window casing a half-inch undersized on the length and width.

Once he gets the trim cut to fit, the unit should slide easily into the opening

and face-nailed into place once it's leveled.

Being a tight-###, I nearly stroked when I learned the cost of a

double-hung, wooden window that had to be custom ordered because

the size is no longer manufactured.

A former tenant "decided" to demolish an existing window and replace

it with a solid, single pane, plastic, who-knows-what.... :evil: :twisted: :evil: :twisted:

I've been blessed with the appearance of an enthusiastic, young man who's

pretty handy and doesn't mind working as a new tenant. Only, he "Ain't

"real-good" with cabinet making." (his words...not mine.)

"We gotta do something with that window, Sir. That's what's causing all the

water damage."

I had to agree.....but $200.00 for a replacement window on a custom size

was a little too steep for my blood.....or a rental house for that matter.

I thought..........well *^&%$*&..maybe I can do it....

Wasn't real sure..but what the heck. I went scrounging around the barn

and came up with some RE-PURPOSEFUL lumber.

1) Some 3/4" pine 1X12's I pulled out of a dumpster.

2) 1- 8 foot cedar 1X6 that came off of an old hot-frame in my greenhouse.

3) 1- 12 foot 2X4 taken from a horse stall I'm taking apart anyways.

4) For the glass, I used one-eighth inch Lexan plastic. Unbreakable.

Note: All of the above was "free"...I like that price.

Yes.........the trim is OVERSIZED by quite a bit. But, unless I was the one

that took the measurements, I couldn't be exact enough for the new trim

to butt up against the existing lap siding.

I located the center of the window for the young man and told him to do

the same thing with the rough opening. Then measure each side from the

center to the edge of the siding and mark the trim accordingly.

Then.....very carefully use a skill-saw and cut to the ""inside"" of the mark.

He had a funny look on his face as if I was mistaken.

I grinned, "No, trust me, that extra eighth inch will be easily caulked in and

you won't have to make the cut but one time."

He understood my meaning.

Overall, it didn't turn out too bad. I boo-boo'd on the sash-frames by 3/4"

on the top one. That made it "larger/taller" than the lower.

I made the window casing a half-inch undersized on the length and width.

Once he gets the trim cut to fit, the unit should slide easily into the opening

and face-nailed into place once it's leveled.