DoozyWombat

Active member

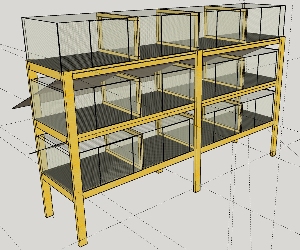

Here is my first attempt at designing a rabbitry. I did this more as an exercise at learning Sketchup than anything else, but I do plan to build from my finished design and use it. When finished, I'll post the full design so others can use it, if they wish. I'm not finished mainly because I have some questions I haven't been able to answer by reading.

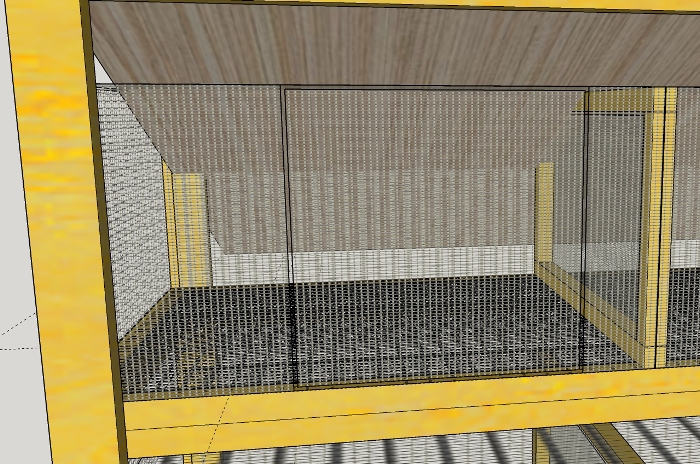

The main concept is for an inexpensive outdoor rabbitry, located in shade. The flooring wire is 1/2" x 2" 14 gauge GAW (galvanized after welding). It is cut in the full 12 foot length, from a 30" roll. The rest of the wire is either going to be 1" hexagonal poultry netting (chicken wire,) or 1" x 2" GAW wire. That's my first question, btw--is one of those better than the other for the sides and top?

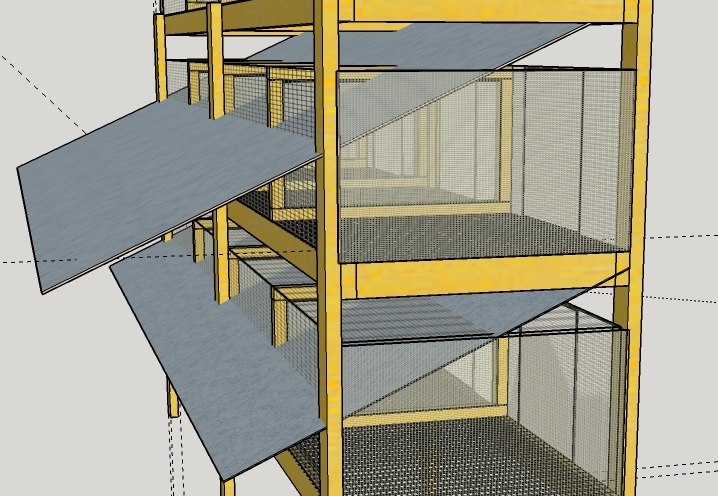

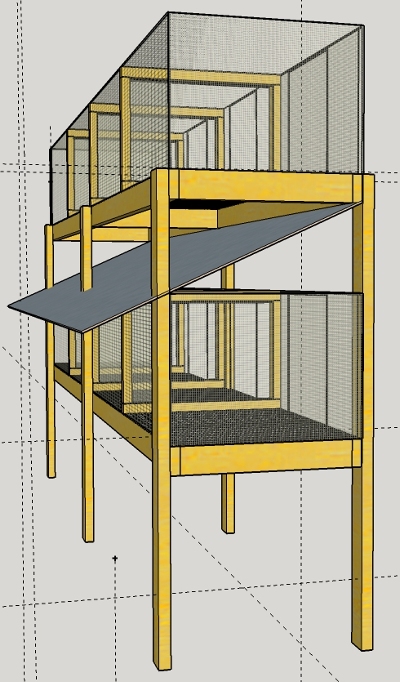

My second question has to do with the poo removal. The slopes under the top two rows are vinyl flooring, to allow poo and urine to move off to the side. I was going to build a gutter system, but after reading through this forum, I have the top row moving off farther than the middle row, and the bottom row allowing everything to fall naturally. I plan to use Miss M's model of deep bedding with chickens, so they scratch in the poo and eat the bugs, but I want to spread out the rows. I'm thinking of literally building this model as part of the wall of the chicken run. My question #2 is, does this angle look steep enough? (I do realize I'm going to have to flash around the wood, cut the cage sections down, and brace under the vinyl.) I just want to know if you think this is a viable model.

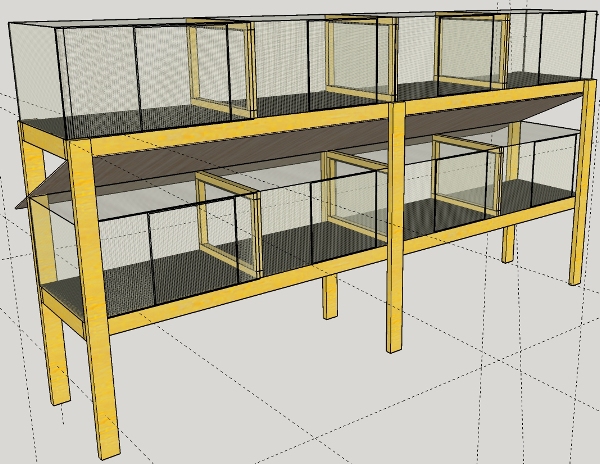

The braces you see between the cages are meant to be movable, if you want to reconfigure the cages at some point. This design has four cages on each row, 36" wide x 30" deep x 18" high. I'm 6'1", so 30" is as deep as I can easily reach. I was going to make the cages smaller, but this gives me four equal cages, all of them a really big space for a buck, or a roomy place for a doe and kits. The cost in materials is really not much between minimal-sized cages and these, so I'd rather give the animals a healthier environment.

I have not included urine guards. That is my next question (#3)--how necessary are they? Some of the things I've read say they are necessary, and some not. The braces are 1" wide with wire on both sides, preventing direct contact. I realize the rabbits might pee through them and hit each other, but will they, and will it matter? Sorry to be ignorant on that. I don't think I can put urine guards on the front of the cages, since that is where feed bins and the doors will be. Any place else they pee is going to land on the ground, and that won't be a problem.

Question #4 is about the doors. I've made them 18" high and wide, so I can easily get in there. I've also offset them to the side, so I have room for the largest possible feeder size. I plan to build a watering system with PVC. But I want the doors to be very large for easy access. My question revolves around where to hinge the doors. I've seen advice that says to hinge them at the top, bottom, and sides. I think at the sides would make the most sense, as hinging at the top would tend to scare the animals as they get pulled out and the door drops down on them, and at the bottom would mean I have to step well away from the cage to get the door open. If I have a struggling animal, that might not be easy. It seems to me that hinging at the sides would be best, but I have no experience. I'm going to make sure I have good latches regardless. What do you say? (Follow-up: I just read the topic from September on exactly this. I'm pretty sure I'm going with side-hinged doors and good latches.)

In case anyone is wondering what I'm planning to do with this, this is a hutch for holding breeding animals and young growouts. Each row can hold a breeding quartet including young, but each cage is large enough for rearing young as well.

Once animals have reached enough size to be safe in them, they will be moved to tractors for the rest of their time. I plan to begin breeding as soon in the year as I expect to have good grass for the tractors when the first kindles get to the right age to go into them. My ultimate goal is to be using the growouts for meat and fur, while breeding for show quality animals and pets. I'm planning to start with Silver Fox, possibly expanding to American Chinchilla over time. As both of those are rare breeds, I plan to do breed maintenance as well. For the present, I plan to keep all breeding stock in the cages.

Temperatures in summer here in Maryland do rarely hit 100F. Summer averages are more like 90F, though, so heat is a major concern. I realize shade is critical, but am still working on plans to deal with heat.

Just as rarely, winter temps occasionally get below 20F, but I'm less concerned about that. I don't plan to breed in cold weather. They will very rarely get below 10F.

There are a number of other factors I'm working out, but these are the ones I'm working on right now. Any and all feedback appreciated.

Thanks very much!

The main concept is for an inexpensive outdoor rabbitry, located in shade. The flooring wire is 1/2" x 2" 14 gauge GAW (galvanized after welding). It is cut in the full 12 foot length, from a 30" roll. The rest of the wire is either going to be 1" hexagonal poultry netting (chicken wire,) or 1" x 2" GAW wire. That's my first question, btw--is one of those better than the other for the sides and top?

My second question has to do with the poo removal. The slopes under the top two rows are vinyl flooring, to allow poo and urine to move off to the side. I was going to build a gutter system, but after reading through this forum, I have the top row moving off farther than the middle row, and the bottom row allowing everything to fall naturally. I plan to use Miss M's model of deep bedding with chickens, so they scratch in the poo and eat the bugs, but I want to spread out the rows. I'm thinking of literally building this model as part of the wall of the chicken run. My question #2 is, does this angle look steep enough? (I do realize I'm going to have to flash around the wood, cut the cage sections down, and brace under the vinyl.) I just want to know if you think this is a viable model.

The braces you see between the cages are meant to be movable, if you want to reconfigure the cages at some point. This design has four cages on each row, 36" wide x 30" deep x 18" high. I'm 6'1", so 30" is as deep as I can easily reach. I was going to make the cages smaller, but this gives me four equal cages, all of them a really big space for a buck, or a roomy place for a doe and kits. The cost in materials is really not much between minimal-sized cages and these, so I'd rather give the animals a healthier environment.

I have not included urine guards. That is my next question (#3)--how necessary are they? Some of the things I've read say they are necessary, and some not. The braces are 1" wide with wire on both sides, preventing direct contact. I realize the rabbits might pee through them and hit each other, but will they, and will it matter? Sorry to be ignorant on that. I don't think I can put urine guards on the front of the cages, since that is where feed bins and the doors will be. Any place else they pee is going to land on the ground, and that won't be a problem.

Question #4 is about the doors. I've made them 18" high and wide, so I can easily get in there. I've also offset them to the side, so I have room for the largest possible feeder size. I plan to build a watering system with PVC. But I want the doors to be very large for easy access. My question revolves around where to hinge the doors. I've seen advice that says to hinge them at the top, bottom, and sides. I think at the sides would make the most sense, as hinging at the top would tend to scare the animals as they get pulled out and the door drops down on them, and at the bottom would mean I have to step well away from the cage to get the door open. If I have a struggling animal, that might not be easy. It seems to me that hinging at the sides would be best, but I have no experience. I'm going to make sure I have good latches regardless. What do you say? (Follow-up: I just read the topic from September on exactly this. I'm pretty sure I'm going with side-hinged doors and good latches.)

In case anyone is wondering what I'm planning to do with this, this is a hutch for holding breeding animals and young growouts. Each row can hold a breeding quartet including young, but each cage is large enough for rearing young as well.

Once animals have reached enough size to be safe in them, they will be moved to tractors for the rest of their time. I plan to begin breeding as soon in the year as I expect to have good grass for the tractors when the first kindles get to the right age to go into them. My ultimate goal is to be using the growouts for meat and fur, while breeding for show quality animals and pets. I'm planning to start with Silver Fox, possibly expanding to American Chinchilla over time. As both of those are rare breeds, I plan to do breed maintenance as well. For the present, I plan to keep all breeding stock in the cages.

Temperatures in summer here in Maryland do rarely hit 100F. Summer averages are more like 90F, though, so heat is a major concern. I realize shade is critical, but am still working on plans to deal with heat.

Just as rarely, winter temps occasionally get below 20F, but I'm less concerned about that. I don't plan to breed in cold weather. They will very rarely get below 10F.

There are a number of other factors I'm working out, but these are the ones I'm working on right now. Any and all feedback appreciated.

Thanks very much!